SELECT DISTINCT shop_view_active_item.*

FROM shop_item_has_category

INNER JOIN shop_view_active_item ON (

shop_view_active_item.company = shop_item_has_category.company AND

shop_view_active_item.shop_code = shop_item_has_category.shop_code AND

shop_view_active_item.language_code = shop_item_has_category.language_code AND

(

shop_item_has_category.item_no = shop_view_active_item.item_no

)

)

WHERE (shop_item_has_category.category_line_no = 159200)

AND shop_view_active_item.language_code = 'ENU'

AND shop_view_active_item.company = 'DESOI'

AND shop_view_active_item.shop_code = 'B2B'

AND shop_item_has_category.company = 'DESOI'

AND shop_item_has_category.shop_code = 'B2B'

AND shop_item_has_category.language_code = 'ENU'

AND shop_item_has_category.category_shop_code = 'B2B'

Add Item to

Shopping Basket

Add all selected Items

to Shopping Basket

Remove Item from Shopping Basket

Add item to favorites

Remove Item from Favorites

Stock Outage

Make a Preorder

Insufficient Stock

Item well stocked

Article in delivery

This item is part of a current campain

DESOI w.i.l.m.a.

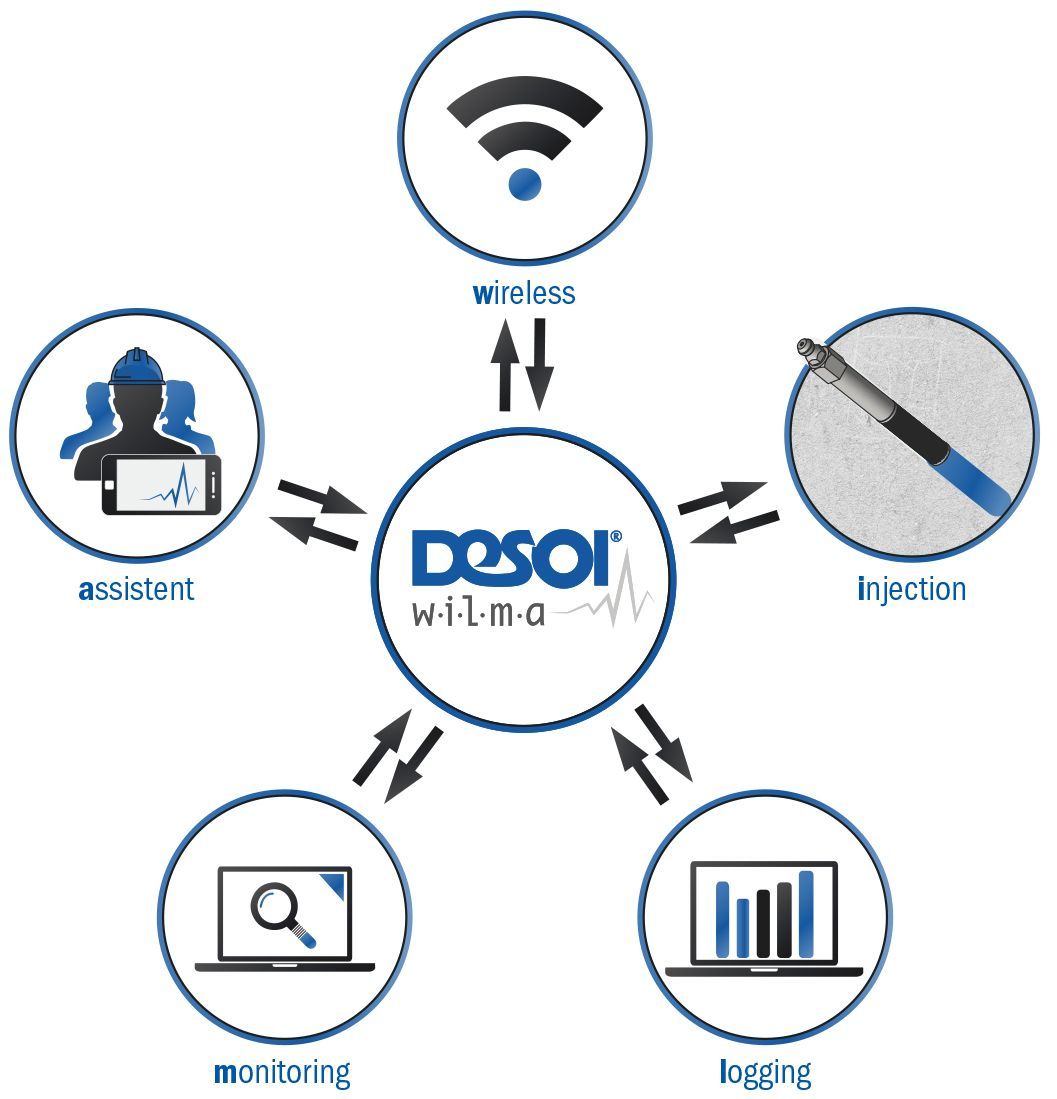

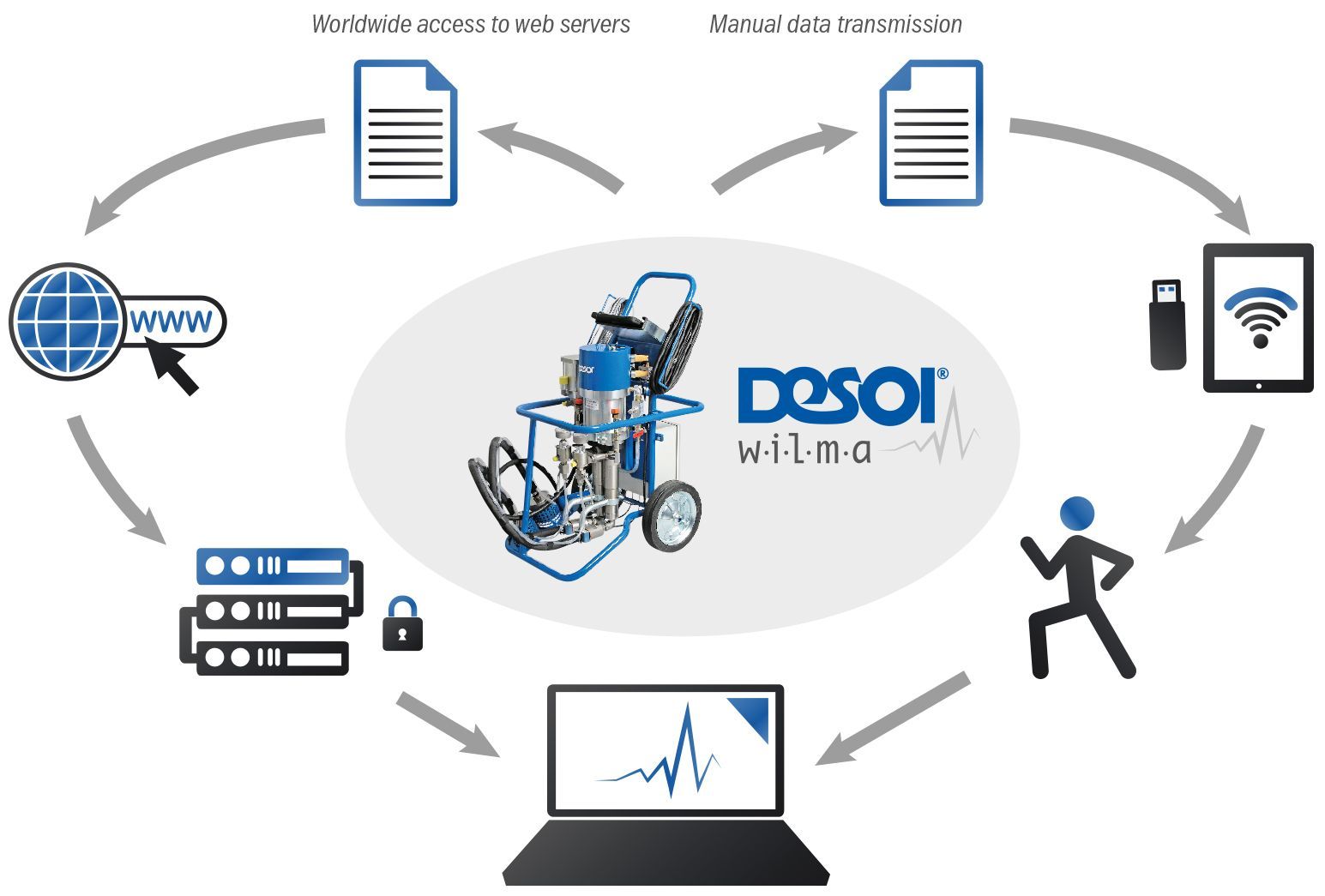

DESOI w.i.l.m.a. stands for wireless injection logging monitoring assistant and is at the heart of the injection pump. State-of-the-art electronics combined with a tablet form an integrated unit and conveniently manage all relevant recording data of the injection process.

DESOI w.i.l.m.a. - Data logger

Documentation of injection processes

open PDF

DESOI w.i.l.m.a.

With the DESOI w.i.l.m.a. recording and documentation device, the integration of mechanics and state-of-the-art electronics has enabled the leap into Industry 4.0.

open PDF

MORE SAFETY FOR INJECTION PROCESSES

DESOI w.i.l.m.a. stands for wireless injection logging monitoring assistant and is at the heart of the injection pump. State-of-the-art electronics combined with a tablet form an integrated unit and conveniently manage all relevant recording data of the injection process.

The data logger, which has been successfully used worldwide for several years, is connected directly to the injection pumps and reliably records the pressure, volume, time and deviation of the injection processes. DESOI w.i.l.m.a. combines a series of innovative injection pumps for various construction processes and documents them securely in accordance with the specifications of quality and construction management. All collected data for further evaluations is, with an existing mobile connection, directly transferred from the device to a central server on request.

PERMANENT DATA RECORDING

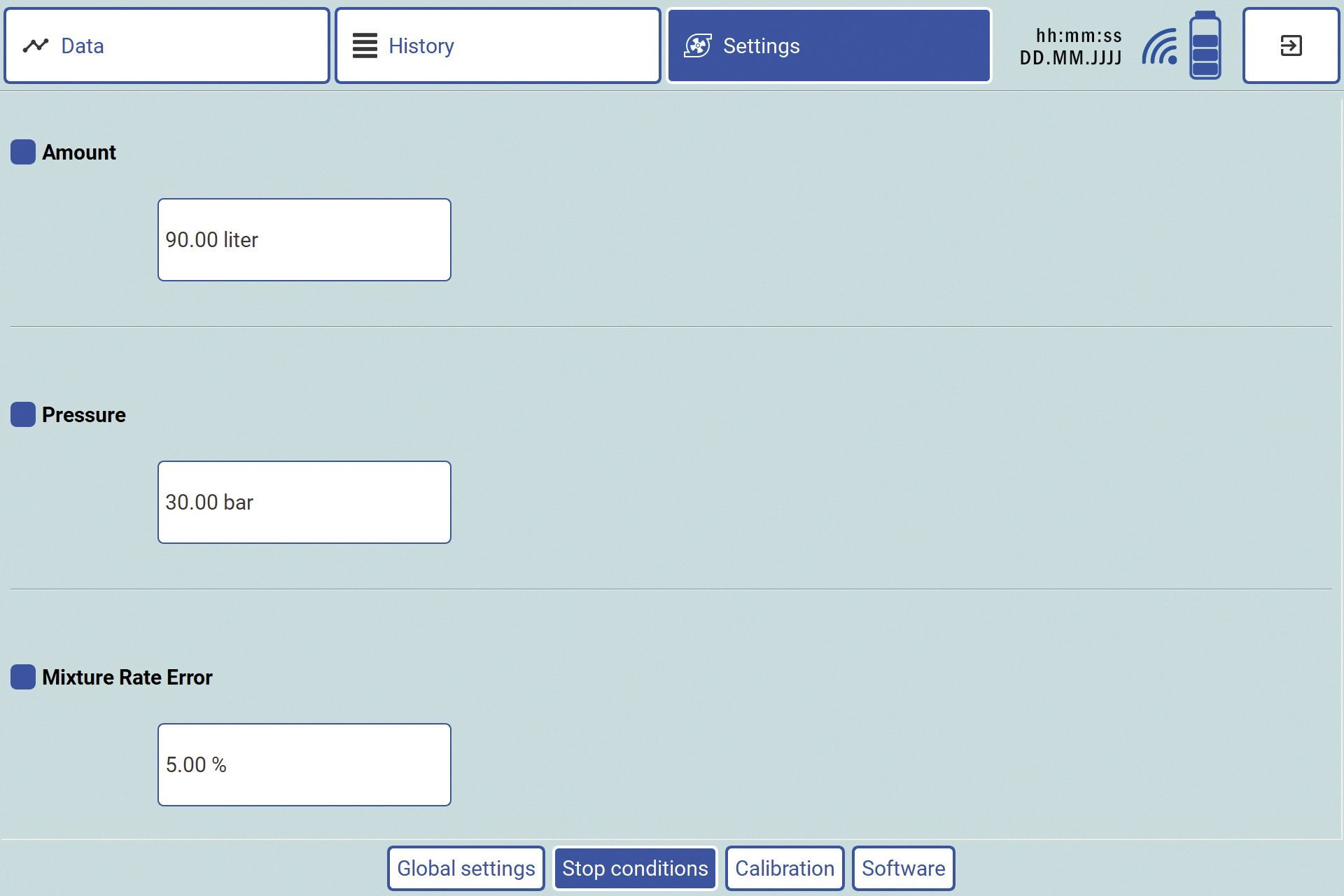

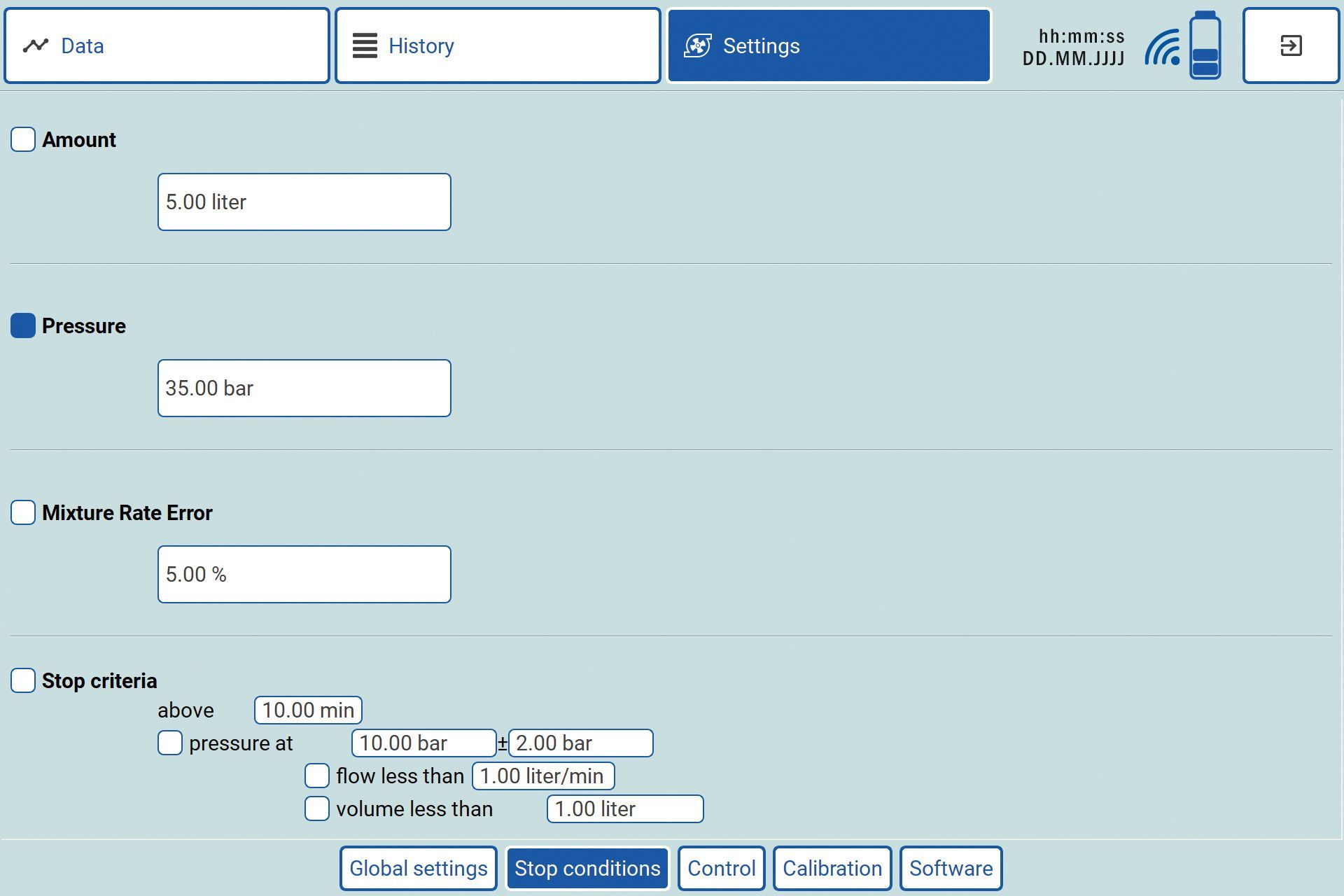

Monitoring during injection work: Through the continuous monitoring of injection processes, it is ensured that the planned parameters can be tailored, monitored and documented specifically for the respective building. In advance, limit values are set, for example, for the mixing ratio, the pressure and the volume.

If these values are undershot or exceeded, for example, the injection process could be stopped and a corresponding message appears on the display. The recorded data is continuously and securely stored on the DESOI w.i.l.m.a. platform and, if there is an existing mobile phone connection, is immediately stored on a secure server in Germany for further processing.

WORLDWIDE ACCESS TO WEB SERVERS

In cooperation with our partner eguana, we form a joint unit to secure all transmitted data on the SCALES platform. Evaluations, analyses and data can be accessed from any browser-enabled device. Three different service tariffs are available to the end user for this service. Irrespective of this, the data can also be read manually by DESOI w.i.l.m.a..

In principle, communication and transparency are ensured from the time the data is recorded at the construction site. All data is password-protected for the user and is processed and managed exclusively on a server in Germany.

Responsible and efficient data management is ensured, including automatic data reading, remote access to device and diagnostic information, and use via conventional standard browsers – anytime, anywhere.

The server is located in Germany in a certified data centre and is subject to automatic version and security updates as well as certified data encryption.

MANUAL DATA TRANSMISSION

- Data download via USB-C or WLAN in CSV format

Manual access to the data is generally possible. However, this way requires more time and effort for the evaluation compared to the automatic method. Furthermore, there is a risk of errors by the operator, which can lead to inaccuracies in the logs. Even a repetition of the same protocols is not 100 % secure if they are created manually. Manually created protocols can only be partially supported by support mechanisms. In addition, it should be noted that managing data on USB memory and transferring it to other media is potentially error-prone.

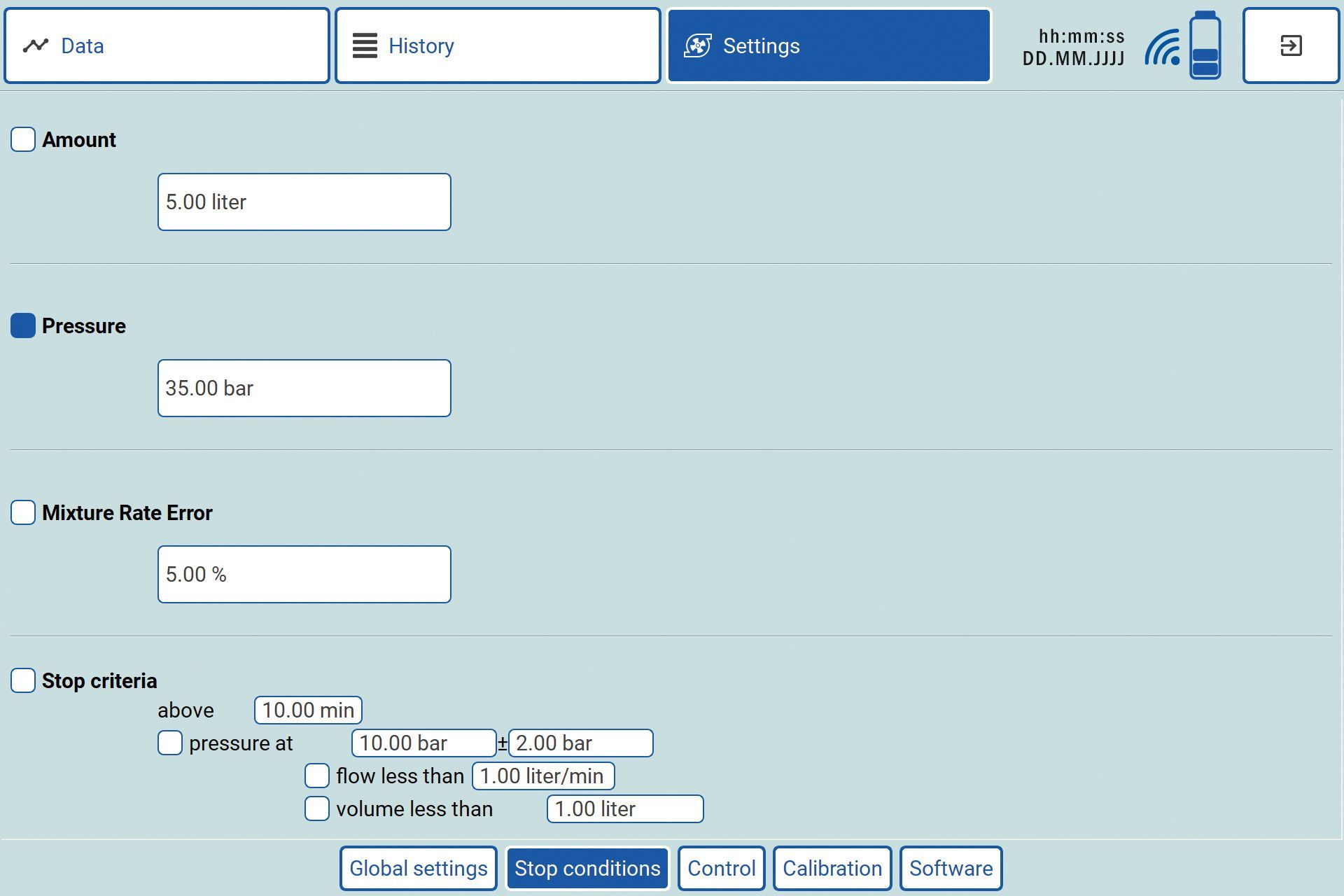

ABORT CRITERION

The system can switch off automatically at

- Reaching the set material consumption

- Reaching the set injection pressure

- Inadmissible exceeding of the mixing ratio

DESOI w.i.l.m.a. documents

- Material consumption per packer

- Mixing ratio

- Injection pressure per packer

- Injection duration per packer

- Order of injections

- Re-injections

- Date and time of injection

DESOI offers the following services

- Individual technical consulting

- Expert on-site instruction on the system

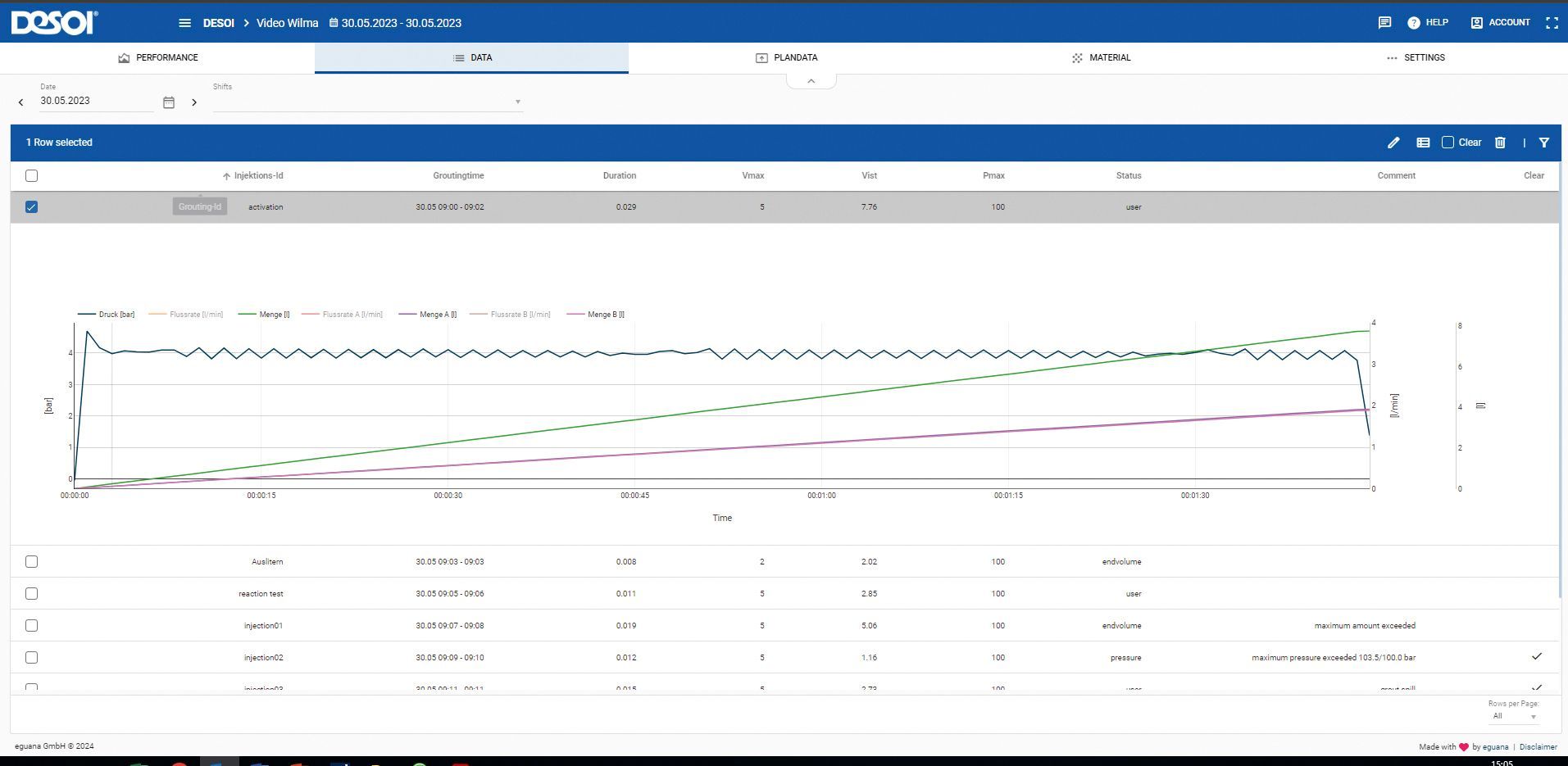

EVALUATION

Intuitive visualisations, automatic analyses and customised reports offer a wide range of possibilities for presenting stored data transparently. Of course, you can also subsequently transfer the data to higher-level systems or export it as a CSV file.

Responsible & efficient data management

- Automatic data acquisition

- Intuitive visualisations:Display of current and historical data in tabular and graphical presentation

- Smooth cooperation for all parties involved

- Real-time access

- Logging: audit-proof data backup

- Export for further processing in higher-level programs (PDF, CSV, and many more)

DESOI w.i.l.m.a. - PRO VErsion

All marked DESOI w.i.l.m.a.'s can be upgraded to the PRO version. The PRO version contains an additional termination criterion and electronic pressure control.

Abort criterion: Pressure holding time

The set pressure is kept constant for a specified time to ensure optimum filling of all cracks and cavities. This is recorded and traceable in the injection log.

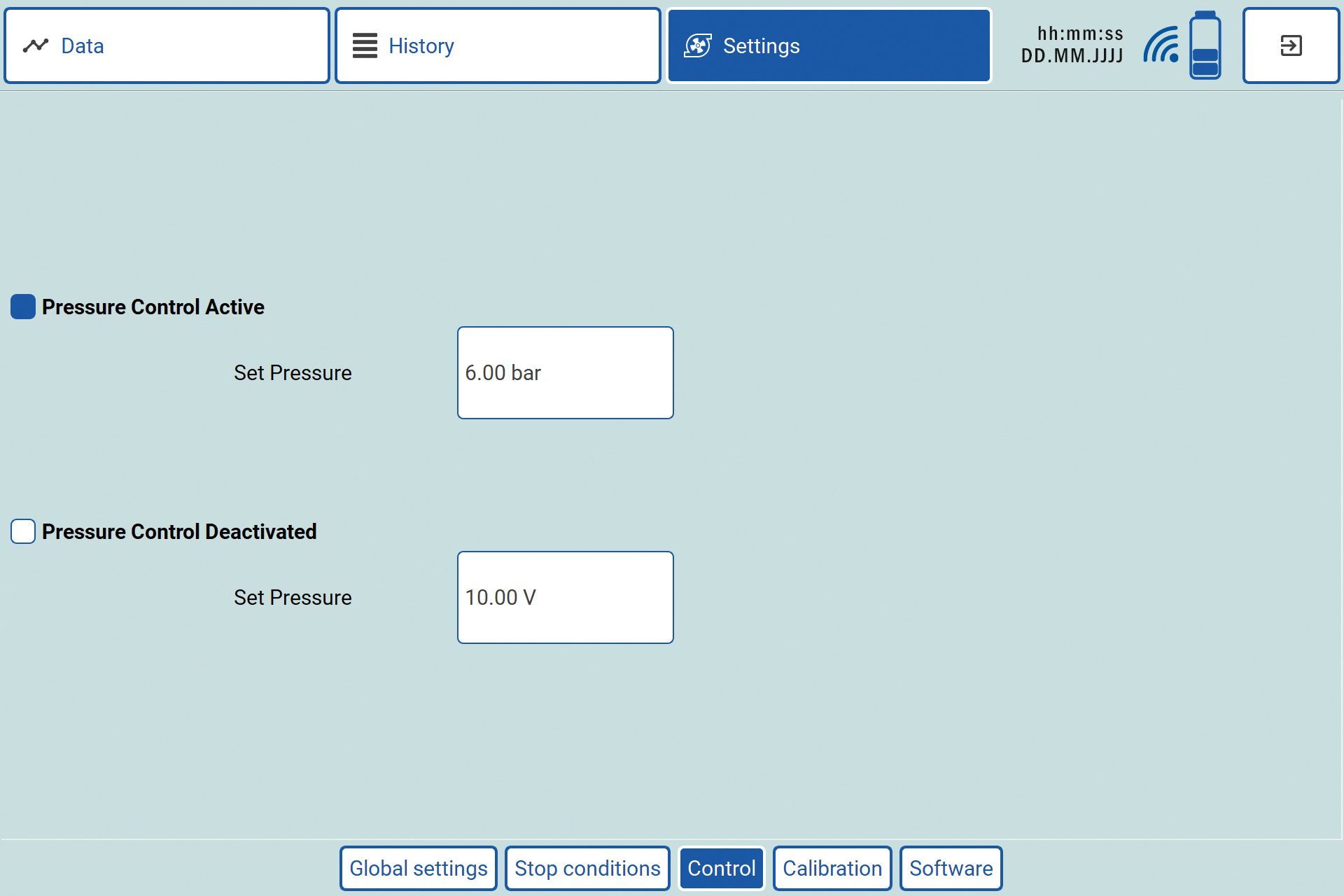

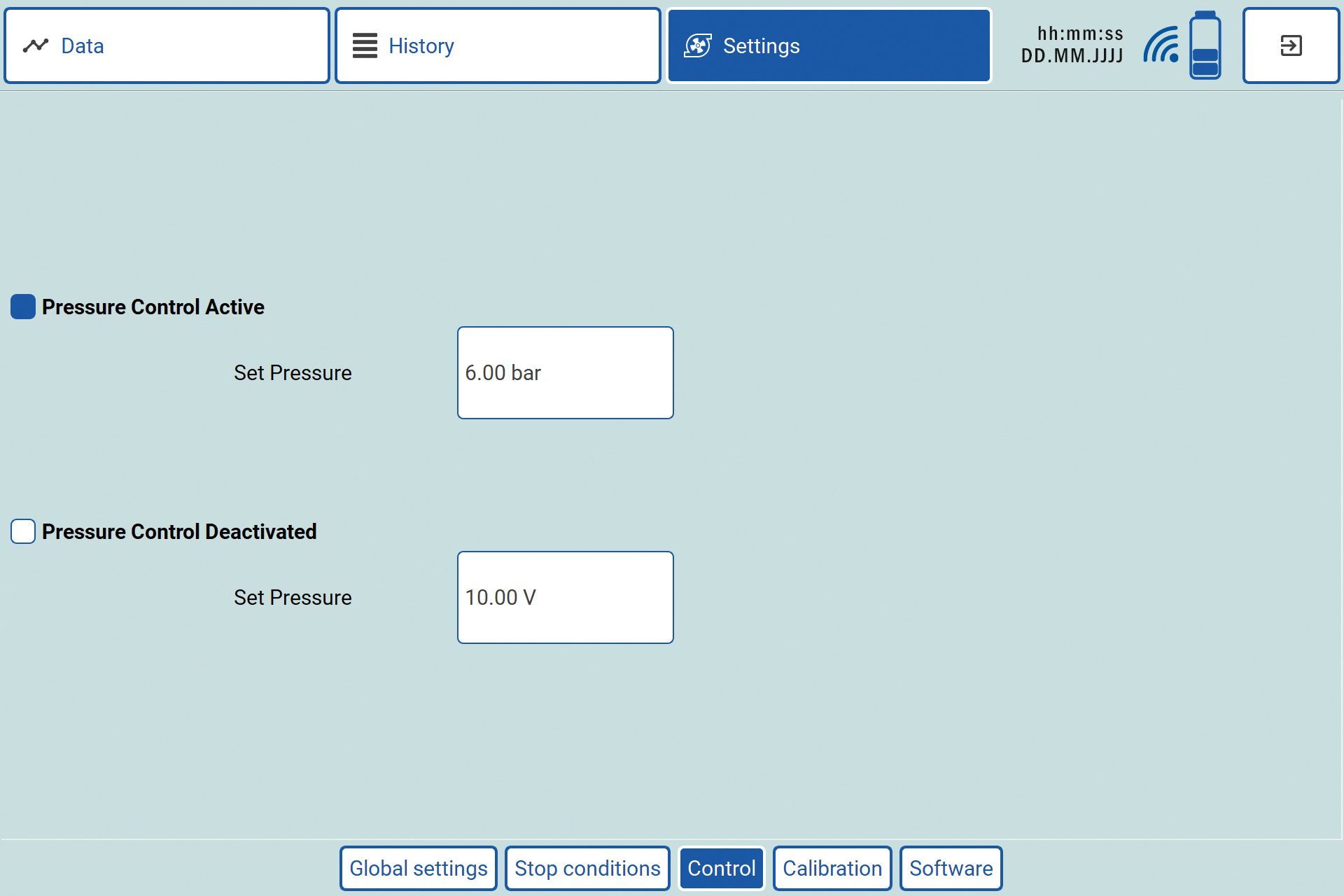

Electronic pressure control

When the electronic pressure control is activated, it is ensured that the set pressure is not exceeded (short-term pressure deviations may occur due to machine shutdown).

Cancellation criteria (pressure holding time)

Cancellation criteria (pressure holding time)

Electronic pressure control

Electronic pressure control